-

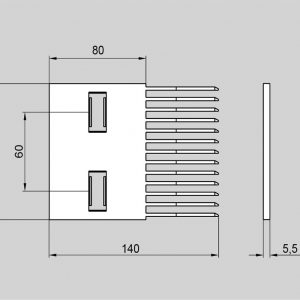

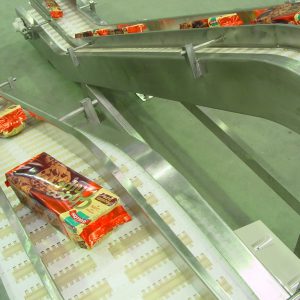

E20 – FINGER PLATES

They have been designed to be used with the Raised Rib belt in applications of intersection of lines in which it is necessary to transfer the product by means of finger plates.

The finger plates are manufactured in nylon and acetal. They have 13 teeth that hide among the projecting ribs of the belt, allowing the constant flow of product as the belt is engaged. They avoid the use of conventional dead plates and consequently the problems by stumbling and fall of the product.

They have two fastening holes that enable little displacements to achieve a better coupling with the belt.

Those holes are located so that they reduce to the minimum the vibrations owing to the turn of the belt over the sprockets.The finger plates can be easily installed in the structure of the conveyor putting a screw in each hole. The dimensions of these screws are: M 6 x 19 mm.

-

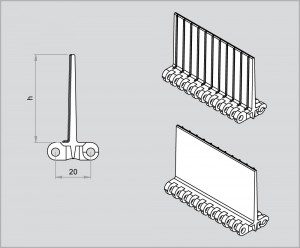

E20 – FLIGHTS AND SIDE GUARDS

STRAIGHT FLIGHT [STREAMLINE + NO CLING]

Height (h):

25 mm

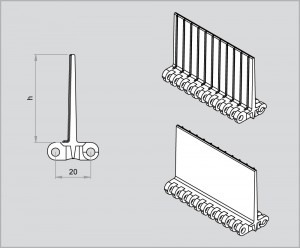

50 mmSIDE GUARDS

The side guards are plastic accessories to be inserted into the belt structure to retain the product laterally, avoiding overflows and frictions with the conveyor structure itself.

Height (h):

50 mm -

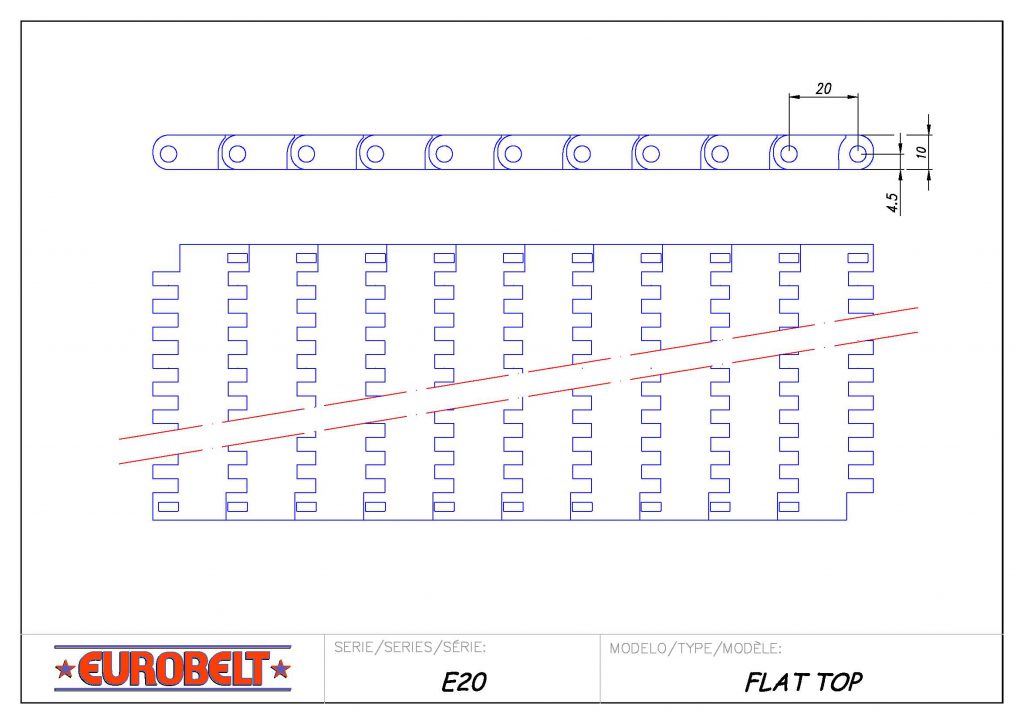

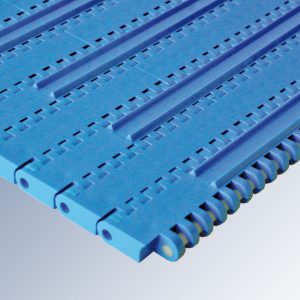

SERIES – E20 – FLAT TOP

-

SERIES – E20 – FLUSH GRID

• Pitch = 20 mm

• Open area = 32%

• Thickness = 9 mm

• Rod diameter = Ø 4.6 mm

-

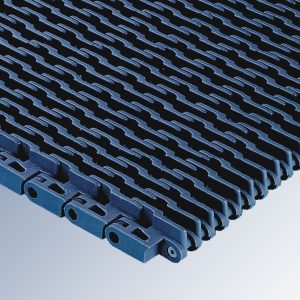

SERIES – E20 – RAISED RIB

• Pitch = 20 mm

• Open area = 32%

• Thickness = 15 mm

• Rod diameter = Ø 4.6 mm

-

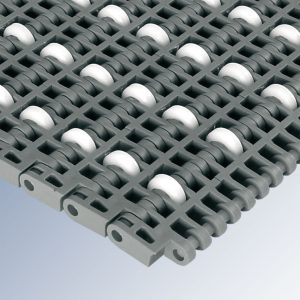

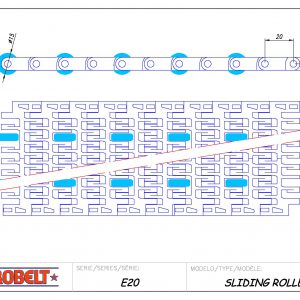

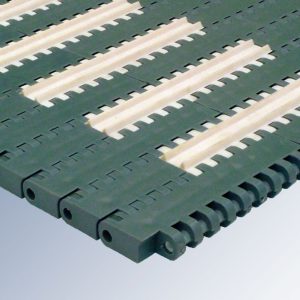

SERIES – E20 – SLIDING ROLLERS

• Pitch = 20 mm

• Surface = Sliding rollers

• Roller diameter = Ø 15 mm

• Rod diameter = Ø 4.6 mm

-

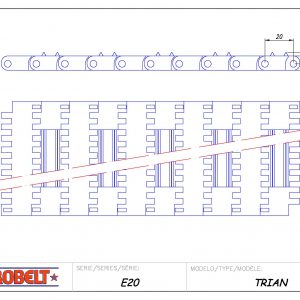

SERIES – E20 – TRIAN

• Pitch = 20 mm

• Surface = Non-stick

• Thickness = 10 mm

• Rod diameter = Ø 4.6 mm

-

SERIES – E20 – TRIAN FRICTION

• Pitch = 20 mm

• Surface = Non-skid

• Thickness = 10 mm

• Rod diameter = Ø 4.6 mm

- Home

- Shop

- Plastic Modular Eurobelt

- SERIES E20