-

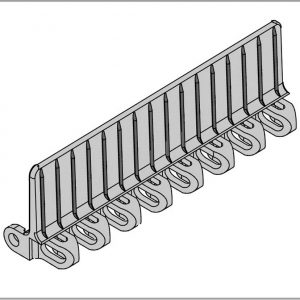

E93 – FLIGHTS

The flights are plastic accessories to be inserted across the belt. They are used to push the product in ascent, descent or accompaniment applications, avoiding that it slips along the belt.

• Its non-stick side has ribs that project over the surface to prevent the product from sticking.

• Their edges are completely rounded to avoid any damage of the product.

• They can be used both in right and in curve sections.It is possible to cut down the standard height for special applications.

-

E93 CURVES – CONIC

Eurobelt Series E93 Conic has a smooth surface with small conic-shaped projections that provide a greater coefficient of friction, as well as they avoid the slippery products to change their position during the conveyance.

-

E93 CURVES – CONIC FRICTION

Eurobelt Series E93 Conic Friction Top is a conveyor belt with modules made in rubber which are inserted among the rest of modules of the belt in order to obtain good friction mechanical properties in applications which require so.

These rubber modules have conic-shaped projections which enable the execution of elevating and/or descending conveyors for manipulation of boxes or containers. -

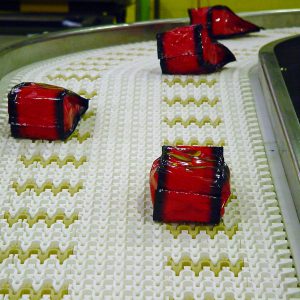

E93 CURVES – FLUSH GRID WITHOUT EDGE TAD

Eurobelt Series E93 Flush Grid without edge tab enables all kind of turns whose minimum radius is 2.2 times the belt width.

This conveyor belt has Flush Grid geometry, with a 47% open area, and smooth and rounded edges, which provides an excellent drainage, a very easy cleaning, good sliding properties, as well as very low maintenance costs. -

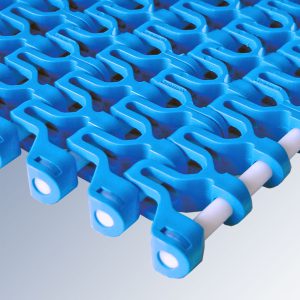

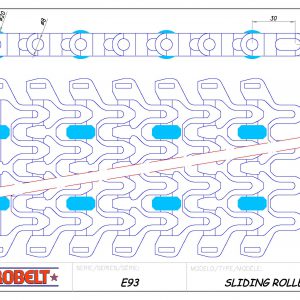

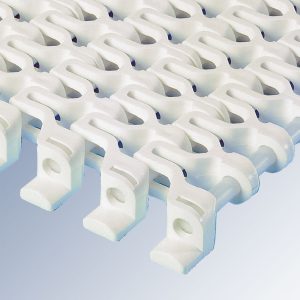

E93 CURVES – SLIDING ROLLERS

Eurobelt Series E93 Sliding Rollers is provided with small rollers inserted on its surface that rotate around themselves whenever there is product accumulation, avoiding crushing and wear in the base of the product.

This conveyor belt has been designed mainly to solve problems of conveyance of boxes, containers, etc. -

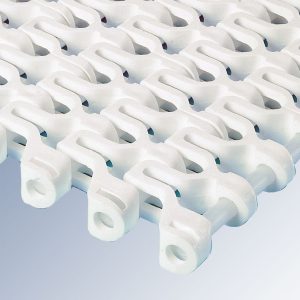

E93 CUSERIES RVES FLUSH GRID WITH EDGE TAD

Eurobelt Series E93 Flush Grid with edge tab has been designed to enable all kind of turns whose minimum radius is 2.2 times the belt width.

Their tabs are lateral ends located in the lower edge of the belt and are used to fasten it without interfering in the transport area, so that the product can exceed the belt width in the turns.

The rounded shape of the tabs reduces the points of friction with the hold-down profiles, which contributes to increase the life of the belt.

- Home

- Shop

- Plastic Modular Eurobelt

- SERIES E93