-

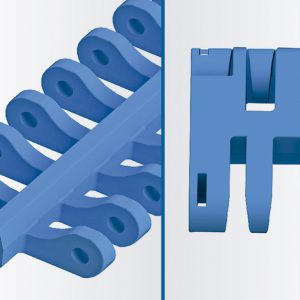

A24 – FINGER PLATES

-

A24 – FLIGHTS AND SIDE GUARDS

STRAIGHT FLIGHT [STREAMLINE + NO CLING]

Height (h):

25 mm

50 mmSIDE GUARDS

The side guards are plastic accessories to be inserted into the belt structure to retain the product laterally, avoiding overflows and frictions with the conveyor structure itself.

Height (h):

50 mm -

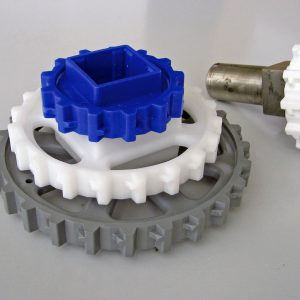

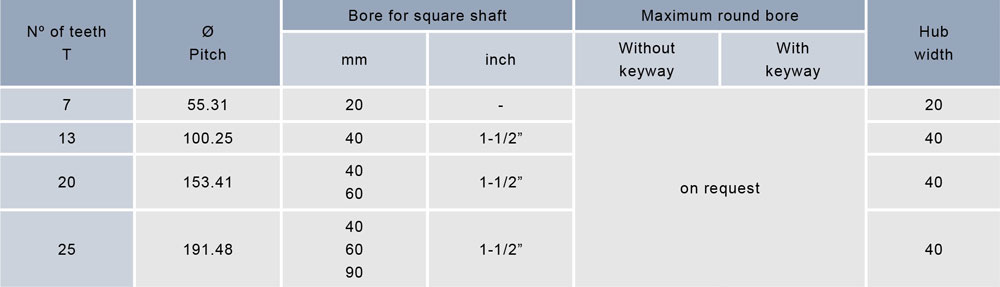

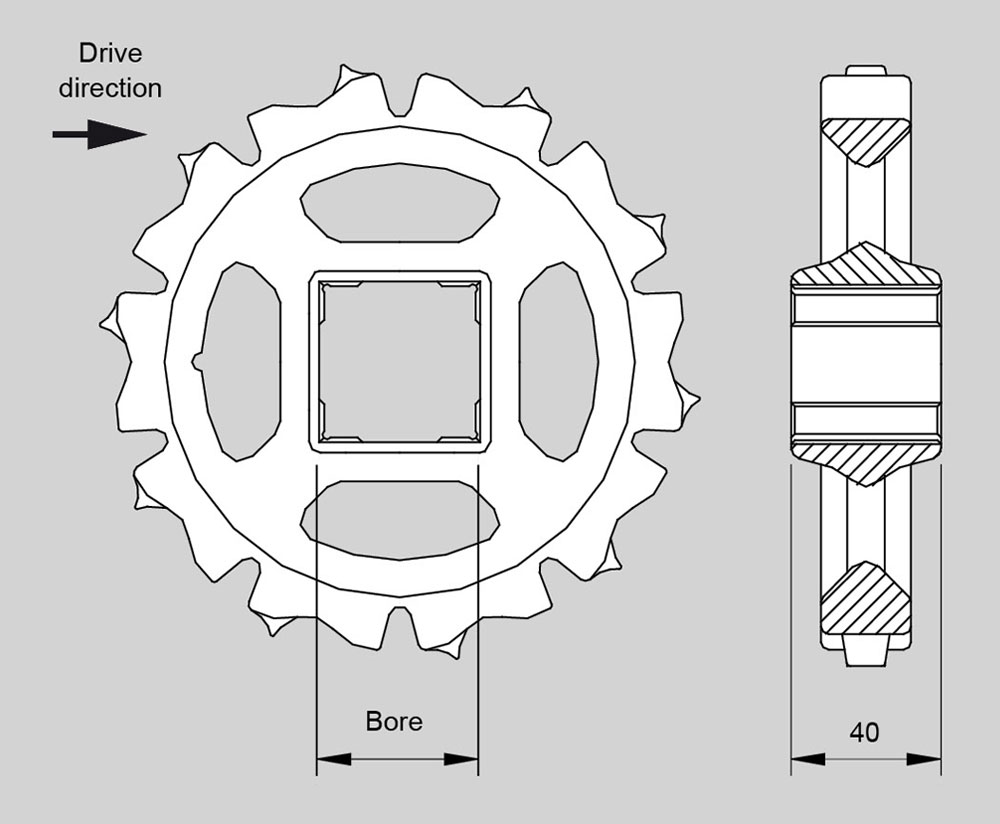

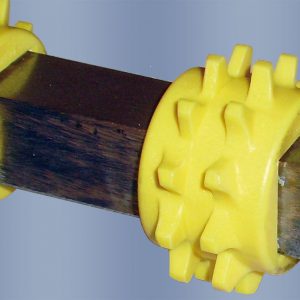

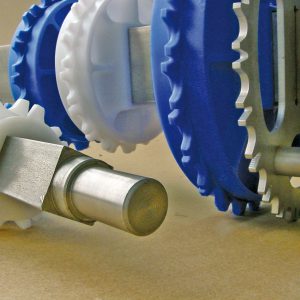

A24 – SPROCKETS

We also have sprockets to be used with motor drum in applications needing a special cleaning or in conveyors in which it is not possible to place the motor in the outside due to problems of space or safety.

To calculate the necessary minimum quantity of sprockets for the drive shaft as well as for the idle one, the next formula has been used:

This quantity must always be odd.

-

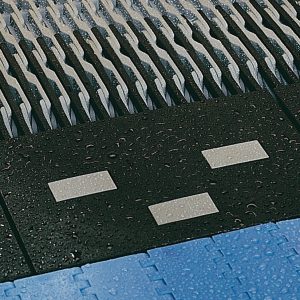

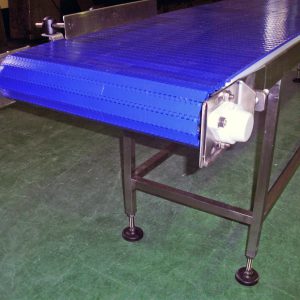

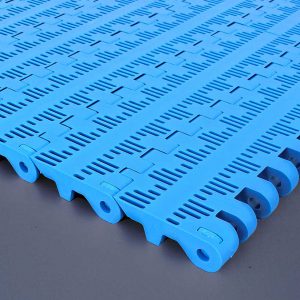

B50 – FLAT TOP

Eurobelt Series B50 Flat Top is the most hygienic and strongest conveyor belt for the food industry. Thanks to its design of completely rounded corners and open edges we avoid the accumulation of debris.

The underside transversal drive bar and the sprockets design make this belt be the best alternative for longer conveyors with heavier loads.

It is recommended for sorting and inspection tables, cut and quartering lines, selection tables, receiving hoppers, etc. -

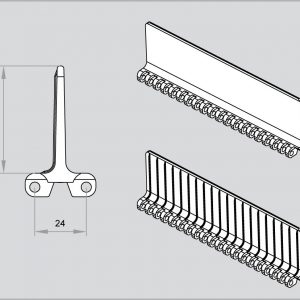

B50 – FLIGHTS AND SIDE GUARDS

The flights are plastic accessories to be inserted across the belt. They are used to push the product in ascent, descent or accompaniment applications, avoiding that it slips along the belt.

• Its non-stick side has ribs that project over the surface to prevent the product from sticking.

• Their edges are completely rounded to avoid any damage of the product.It is possible to cut down the standard height for special applications.

Materials: Polypropylene – Polyethylene – Polyacetal

-

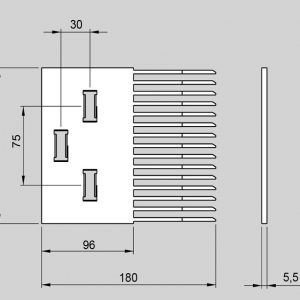

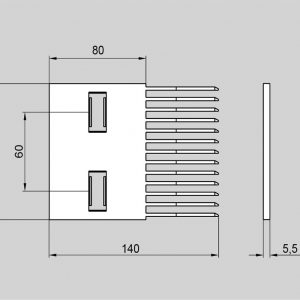

B50 – FLUSH GRID

SERIES – B50 – FLUSH GRID

Pitch = 50 mm

• Open area = 28%

• Maximum opening = [11.6 x 10.4] mm

• Thickness = 16 mm

• Rod diameter = Ø 5.5 mm

-

B50 – PERFORATED

Its smooth perforated surface allows the air to flow and the liquids to drain away.

It is the ideal belt for production food processes (boiling, draining, drying) as well as for preservation processes (sterilization, refrigeration).

Its design of totally rounded edges and its greater opening in the joint area make easier the water draining as the belt is cleaned which reduces to the minimum the waste accumulation. -

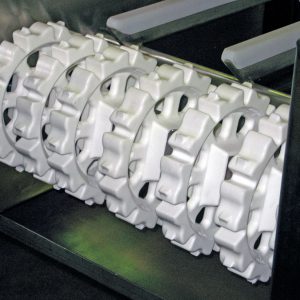

B50 – SPROCKETS

-

C12 – Sprockets

-

E20 – FINGER PLATES

They have been designed to be used with the Raised Rib belt in applications of intersection of lines in which it is necessary to transfer the product by means of finger plates.

The finger plates are manufactured in nylon and acetal. They have 13 teeth that hide among the projecting ribs of the belt, allowing the constant flow of product as the belt is engaged. They avoid the use of conventional dead plates and consequently the problems by stumbling and fall of the product.

They have two fastening holes that enable little displacements to achieve a better coupling with the belt.

Those holes are located so that they reduce to the minimum the vibrations owing to the turn of the belt over the sprockets.The finger plates can be easily installed in the structure of the conveyor putting a screw in each hole. The dimensions of these screws are: M 6 x 19 mm.

-

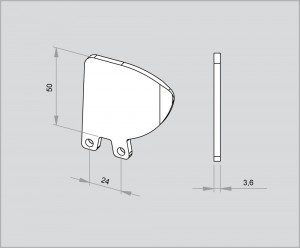

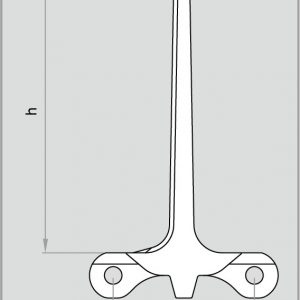

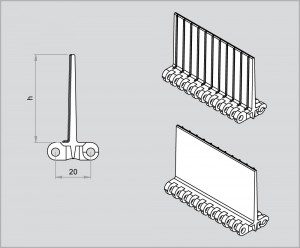

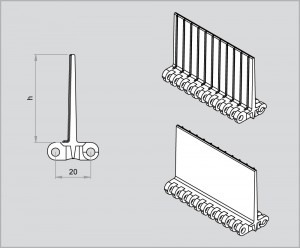

E20 – FLIGHTS AND SIDE GUARDS

STRAIGHT FLIGHT [STREAMLINE + NO CLING]

Height (h):

25 mm

50 mmSIDE GUARDS

The side guards are plastic accessories to be inserted into the belt structure to retain the product laterally, avoiding overflows and frictions with the conveyor structure itself.

Height (h):

50 mm -

E20 – SPROCKETS